In the realm of lead-acid batteries, one technical factor stands out as a primary differentiator of performance and application: plate thickness. This often-overlooked design element is not merely a manufacturing detail—it is the backbone of classifying batteries for specific use cases, from powering car engines to sustaining marine vessels and off-grid systems. For engineers, technicians, and industry decision-makers, understanding how plate thickness shapes battery functionality is critical to selecting the right solution for any application. Let’s break down this relationship, with a focus on three high-demand categories: AGM Start Stop Batteries, Marine/RV Batteries, and AGM Deep Cycle Batteries.

The Thin-Plate Advantage: AGM Start Stop Batteries

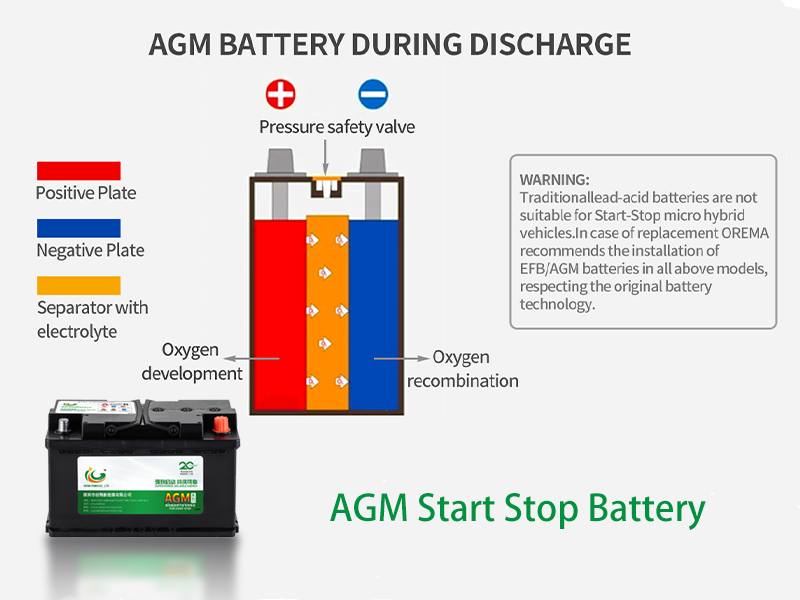

When it comes to automotive ignition, the priority is instant, high-current delivery—a requirement that hinges on thin lead plates. This is precisely why AGM Start Stop Batteries (a premium subset of starter batteries) are engineered with slim, densely packed plates. Unlike traditional starter batteries, AGM (Absorbent Glass Mat) technology enhances this design by immobilizing the electrolyte, reducing internal resistance and enabling faster energy release.

The thin-plate structure of AGM Start Stop Batteries maximizes the surface area in contact with the electrolyte, a key factor for generating the short bursts of power needed to crank an engine—even in stop-start systems, where the battery cycles hundreds of times daily. This design also prioritizes compactness, making it ideal for modern vehicles with limited under-hood space. Crucially, while thin plates excel at high-current output, they are not built for deep discharge; their strength lies in rapid recharge and repeated, brief energy bursts—exactly what start-stop applications demand.

The Hybrid Solution: Marine/RV Batteries (Bridging Starter and Deep Cycle Needs)

Marine and RV applications present a unique challenge: they require both the high cranking power to start engines and the ability to sustain low, continuous power for lights, pumps, or appliances—often for hours on end. This is where Marine/RV Batteries shine, as they are intentionally designed as a hybrid of starter and deep cycle technologies, with plate thicknesses that balance both needs.

To achieve this versatility, Marine/RV Batteries combine two plate types:

Thin plates (similar to AGM Start Stop Batteries) for delivering the initial cranking power to start boat engines or RV generators.

Thicker, heavier plates (borrowed from deep cycle designs) for enduring repeated deep discharges—critical when powering onboard systems without access to shore power.

This hybrid plate configuration ensures Marine/RV Batteries can handle the “best of both worlds”: they won’t fail when asked to start an engine, and they won’t degrade prematurely after being drained to 50% capacity (a common scenario in off-grid marine/RV use). For users, this means no need to carry two separate batteries—one for starting, one for house power—saving space and simplifying maintenance.

The Thick-Plate Workhorse: AGM Deep Cycle Batteries

For applications where long-duration, deep discharge is the norm—such as solar energy storage, off-grid RV “house” power, or industrial backup systems—thick lead plates are non-negotiable. This is the domain of AGM Deep Cycle Batteries, which are engineered with robust, thick plates to prioritize cycle life and sustained energy output over instant power.

Thicker plates contain more active material and are structured to withstand the mechanical stress of repeated charging and discharging cycles. In AGM Deep Cycle Batteries, this design is paired with AGM technology to eliminate electrolyte spillage, improve thermal stability, and extend service life—often up to 1,000 deep cycles (vs. 200–300 cycles for standard flooded deep cycle batteries).

Unlike AGM Start Stop Batteries, which are optimized for short bursts, AGM Deep Cycle Batteries excel at releasing energy slowly and consistently. For example, in a solar system, they can store energy collected during the day and discharge it gradually overnight to power a home. In RVs, they serve as dedicated “house batteries,” powering refrigerators and lights without risking the ability to start the vehicle (that task falls to a separate starter battery or a hybrid Marine/RV Battery).

The Bottom Line: Plate Thickness = Application Suitability

At its core, the classification of lead-acid batteries boils down to plate thickness—and understanding this relationship is the key to avoiding costly mismatches. To recap:

Thin plates = High current, short bursts (AGM Start Stop Batteries for automotive use).

Hybrid thin/thick plates = Balanced cranking power and deep discharge (Marine/RV Batteries for versatile off-grid use).

Thick plates = Long cycles, sustained discharge (AGM Deep Cycle Batteries for solar, backup, and house power).

For industry professionals, this knowledge empowers smarter specification: choosing an AGM Start Stop Battery for a fleet of delivery vans, a Marine/RV Battery for a weekend boating trip, or an agm deep cycle battery for a remote solar installation isn’t just about brand or price—it’s about matching plate design to the application’s unique energy demands.

In a market saturated with battery options, plate thickness remains the unifying technical principle that separates “good” batteries from “right” ones.